hankyoreh

Links to other country sites 다른 나라 사이트 링크

LG Chem, GM to start joint venture on EV battery production

The competition is heating up among companies looking to capture the market for batteries as key components in electric vehicles ahead of a full-scale global electric vehicle production race in 2020.

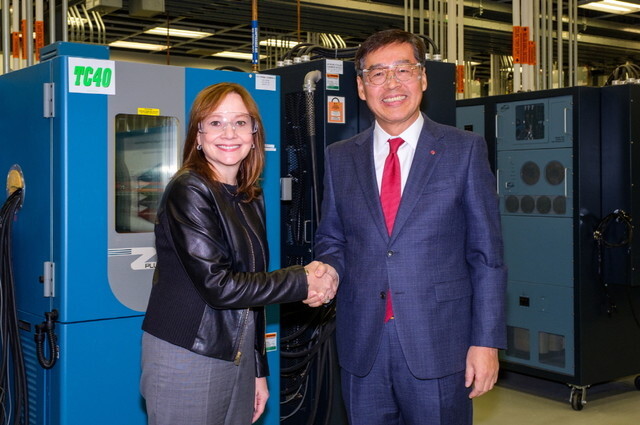

On Dec. 6, LG Chemical (LG Chem) signed a contract to collaborate with GM, the top-ranked company in the US automobile industry, on an electric vehicle battery cell factory at a scale of 2.7 trillion won (US$2.26 billion). The batteries produced at the factory, on which construction is set to begin in the US in mid-2020, are to be 30Gwh units to power electric vehicles produced by GM. On Dec. 5, SK Innovation completed construction of the “BEST” electric vehicle battery cell factory -- a collaboration with Beijing Automobile Works (BAW), which ranks second for electric vehicle sales in China -- with plans to supply batteries for Chinese electric vehicle production as of early next year.

South Korean battery companies have been stepping up their overseas investment since the early 2010s, but the establishment of joint battery corporations with finished automobile companies has been a notable recent phenomenon, as in the two cases here. In June, LG Chem formed a joint battery cell corporation with China’s Geely Auto with a mass-production target date in 2022; SK Innovation has formed a joint venture with the battery company EV Energy -- which has a strong supply network with Germany’s Daimler and other companies with automobile factories in China -- and is currently examining possible factory sites in Yancheng and other locations. Major overseas automobile companies like Volkswagen and Toyota are also joining forces with battery companies to establish battery factories.

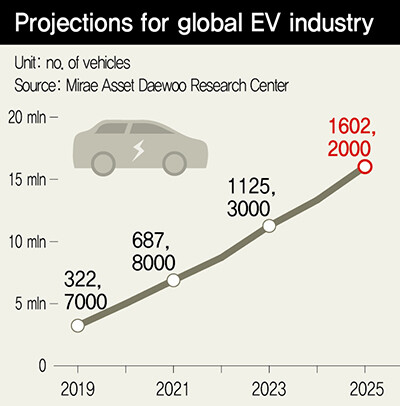

The reason that automobile makers are joining in the establishment of battery factories has to do with the intensifying race to acquire batteries amid a sharp rise in electric vehicle production. According to a report on “projected global electric vehicle market scale” published by the Mirae Asset Daewoo Research Center, the scale of electric vehicle production is expected to grow by over 30% yearly from 3.2 million in 2019 to 16 million won in 2025. The market for batteries as key electric vehicle components was also predicted to reach 94.5 trillion won (US$79.17 billion) by 2023 -- nearly four times the 2019 level of 24.6 trillion won (US$20.62 billion).

According to statistics from the battery market research organization SNE Research, China’s CATL held the top-ranked market share with 26.6% of annual cumulative electric vehicle battery usage as of September 2019, followed by Japan’s Panasonic (24.6%), with China’s BYD and LG Chem tied for third place at 11.0% each. Samsung SDI and SK Innovation respectively ranked sixth (3.5%) and ninth (1.8%).

The Chinese government is also expected to reduce the policy subsidies that have helped usher CATL to industry-leader status -- sending a green-light signal to the South Korean companies fighting the “new Three Kingdoms war” over batteries with China and Japan. Some of the Mercedes-Benz (Beijing branch) electric vehicle models including in an “eco-friendly car recommendation list” published by the Chinese government for November 2019 are to include products made at SK Innovation’s Seosan plant. The Tesla Model 3 (Shanghai branch) is also reportedly set to use batteries by LG Chem.

The opening of the world’s largest electric vehicle market – previously closed off by the Chinese government’s policies to support domestic industry -- is expected to lead to improved profitability for South Korean businesses, which have the edge over China in terms of technical expertise. Previously, Chinese expansion by South Korean battery companies had remained at the level of financial investment.

“Since batteries are a technology-intensive industry, we’re expecting less than 10 ‘survivors’ among the more than 100 Chinese battery companies that have proliferated under government support,” said one battery industry insider.

“With the electric vehicle market growing rapidly and battery production costs gradually falling, we’re going to see more cooperation among finished automobile and battery companies pursuing economies of scale,” the insider predicted.

By Kim Eun-hyung, staff reporter

Please direct comments or questions to [english@hani.co.kr]

Editorial・opinion

![[Column] Has Korea, too, crossed the Rubicon on China? [Column] Has Korea, too, crossed the Rubicon on China?](https://flexible.img.hani.co.kr/flexible/normal/500/300/imgdb/original/2024/0419/9317135153409185.jpg) [Column] Has Korea, too, crossed the Rubicon on China?

[Column] Has Korea, too, crossed the Rubicon on China?![[Correspondent’s column] In Japan’s alliance with US, echoes of its past alliances with UK [Correspondent’s column] In Japan’s alliance with US, echoes of its past alliances with UK](https://flexible.img.hani.co.kr/flexible/normal/500/300/imgdb/original/2024/0419/2317135166563519.jpg) [Correspondent’s column] In Japan’s alliance with US, echoes of its past alliances with UK

[Correspondent’s column] In Japan’s alliance with US, echoes of its past alliances with UK- [Editorial] Does Yoon think the Korean public is wrong?

- [Editorial] As it bolsters its alliance with US, Japan must be accountable for past

- [Guest essay] Amending the Constitution is Yoon’s key to leaving office in public’s good graces

- [Editorial] 10 years on, lessons of Sewol tragedy must never be forgotten

- [Column] A death blow to Korea’s prosecutor politics

- [Correspondent’s column] The US and the end of Japanese pacifism

- [Guest essay] How Korea turned its trainee doctors into monsters

- [Guest essay] As someone who helped forge Seoul-Moscow ties, their status today troubles me

Most viewed articles

- 1[Column] The clock is ticking for Korea’s first lady

- 2Samsung barricades office as unionized workers strike for better conditions

- 3After 2 months of delayed, denied medical care, Koreans worry worst may be yet to come

- 4[Correspondent’s column] In Japan’s alliance with US, echoes of its past alliances with UK

- 5[Column] Has Korea, too, crossed the Rubicon on China?

- 6Hong Se-hwa, voice for tolerance whose memoir of exile touched a chord, dies at 76

- 7[Photo] Smile ambassador, you’re on camera

- 8All eyes on Xiaomi after it pulls off EV that Apple couldn’t

- 9[Guest essay] How Korea turned its trainee doctors into monsters

- 10US overtakes China as Korea’s top export market, prompting trade sanction jitters